Probabilistic planning software achieves radical improvements in evaluating well abandonment methodologies in Australia

Contact us

OVERVIEW

P1™ demonstrated its powerful capabilities in enhancing the quality of engineering required to decide optimum well abandonment methods.

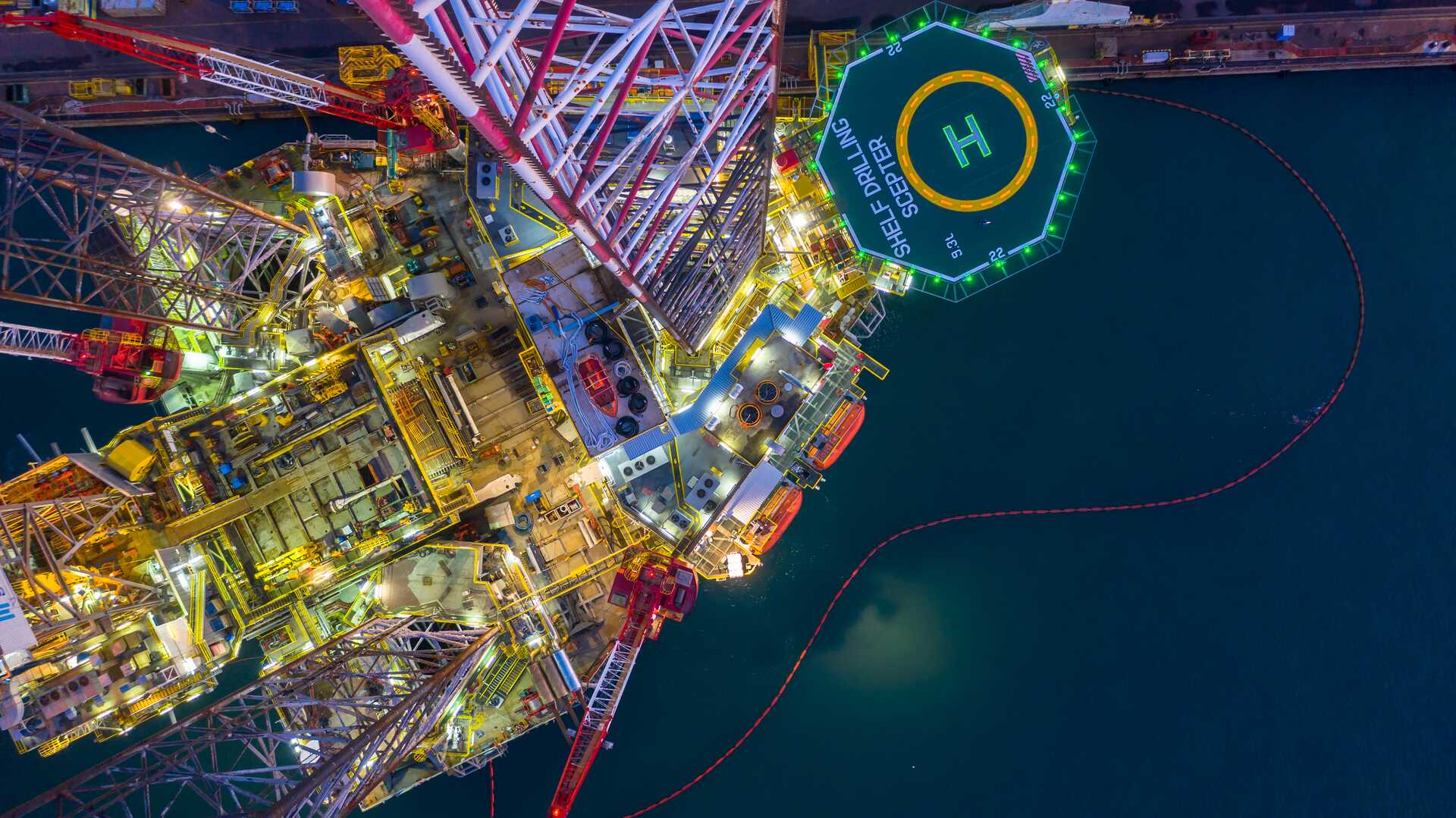

LOCATION: Well decommissioning campaign at the North-West Shelf, offshore Western Australia

THE CHALLENGE

High grade risk assessment of probable decommissioning outcomes was essential

The well in question was of conventional 30" x 20" x 13-3/8" x 9-5/8" design and was completed with sand screens across the reservoir interval. The initial screening process had verified that annular cement was in place across the cap rock and so all lower abandonment options requiring removal of casing were discounted. However, the three alternative abandonment options remained:

- Bullhead cement

- Placement of a balanced cement plug thru-tubing using coiled tubing

- Placement of a balanced cement plug on drill pipe after removal of the upper completion

These decommissioning methods were taken forward for detailed, probabilistic assessment applying the Monte Carlo probabilistic simulation functionality of P1™.

As with all projects of this nature, a comprehensive risk based analysis of all probable outcomes across the three methods was completed.

The operator rightly demanded planning of a high grade to achieve efficient and safe well abandonment methodologies and to be confident that the selected method would not lead to later expensive re-work.

OUR SOLUTION

Outcomes for each of the abandonment methodologies were assessed simultaneously, based on a number of key features from both the cumulative and density functions. Assessing the cumulative function, the option of placing a balanced cement plug set after removing the upper completion, had a very tight spread, no inflection point and no tailing distribution. It was therefore viewed as the lowest risk, most robust abandonment methodology.

Comparing this directly with the coiled tubing placement option showed another tight spread with an inflection point and large tail for P95 and above outcomes (an unlikely outcome). This indicates a lower probability of success assigned to the placement of cement with coil, opposed to drill-pipe in a clear wellbore due to return flow dynamics – a position agreed upon during the peer review process. The time delta between both methods across all “P” outcomes is based on a single well being abandoned and the time taken to rig up and down coiled tubing on a semi-submersible MODU is included.

Extending the assessment to the density function, the option where the upper completion was removed, producing a single, tight band with a high peak. This meant all of the possible outcomes were grouped within a single small range of days, reinforcing the robustness of this option. The coiled tubing counterpart had two bands, the first of which was a tight band with a slightly lower peak showing a large number of outcomes, expected to lay within this band.

The second band, however, was wide with no significant peak. This showed that in a remediation scenario the remaining outcomes are subjected to a large and unpredictable range. Based on these factors, the coiled tubing option was assessed as a poor choice for this wellbore, offering no upside even in the most favourable of scenarios. As a result it was discarded from further engineering work during the detailed planning phase, with this decision supported by a comprehensive set of peer reviewed evidence.

Again, assessing the cumulative function, the bullhead cement option was seen to have a very large spread, two inflection points at the P50 and P90 outcomes and very large tail for P90 and above outcomes. The two inflection points for this model represented scenarios where cement placement was unsuccessful and remediation was required.

The first point showed remediation activities where a drift was run and cement was tagged low, requiring removal of the upper completion, drill-out and cement subsequently placed on drill pipe.

The second showed remediation activities where hydraulic lock occurred and the tubing string was cemented in place, requiring overshot and recovery or mill-out of the entire string. In the case of P50 and below outcomes, a time saving of 2 to 2.5 days was seen when compared directly to the balanced plug option following the removal of the upper completion. For P50 and above outcomes, the time saving was quickly diminished with outcomes experiencing a time increase between 1 day for the first inflection point and 8 days for the second inflection point.

Looking at the density function, the bullheading option showed three distinct bands. The first band was narrow and had a high peak, signalling that a high number of outcomes were expected to lay within this day range. The second, wide band showed the unpredictability of outcomes associated with remediating a poor cement job. A similar area under the curve to the first band showed that a similar number of outcomes were expected to lay within this range. This reinforced the riskiness of this method. The final, narrow band had a small peak with the area under this curve, suggesting that only a small number of outcomes were expected to occur for this large number of days.

From this, it can be concluded that the bullhead cement option offered a high risk, high return alternative to P&A, where a successful operation had the opportunity to save a few days of rig time. In contrast, an unsuccessful operation results in significant downside and a dramatic increase in the number of days required to place the lower abandonment plug. With the chance of saving a few days of rig time, this option was assessed to offer an opportunity case and taken forward into the detailed planning phase to see if risks could be addressed and project confidence increased. As the drill pipe conveyed, cement plug option was still considered to offer the most robust solution and was accepted as the base case abandonment methodology.

THE OUTCOME

A comprehensive risk-based well decommissioning assessment of all drilling scenarios

This detailed, probabilistic modeling for each abandonment methodology provided a comprehensive risk based assessment of all probable outcomes, enabling:

- With peer reviews to be held at different stages, to align on percentages assigned and the assumptions used.

- The well documented, methodical approach allowed the team to efficiently select the base case, opportunity cases and discarded cases and to take these forward into the detailed planning phase.

- Knowing that there are a number of adverse outcomes allowed for well targets to be accurately set, while also ensuring an adequate contingency budget was allocated should well conditions be found to be unfavourable.

- The avoidance of poor abandonment methodologies achieved with the software, and the robust set of supporting documentation it provides, prevents the reworking of different options at a later date. This saves time and resources during detailed planning.

- The transparent and collaborative methodology used overcomes individual bias and provides a quantitative, robust and fair assessment of every methodology available for abandonment.

- Detailed time models are created early in the piece and used as a solid framework when developing AFE models, which again saves time.

- Visual representations of risk and the large number of probable outcomes when progressing through an abandonment was important when articulating challenges and collaborating across departments to align on key decisions.

WHAT VALUE DID iQx™ BRING?

P1 offers a full in-depth estimation of all probabilistic decommsioning outcomes

- Remaining abandonment options were broken out into a separate model.

- Representative models were built like-for-like to allow direct comparison. For example, a thru-tubing option not requiring removal of SST to place cement was compared directly to an option requiring removal of the SST if the tree had to be removed as part of the next operation.

- Detailed series of events were built for each methodology. Risks identified, assigned to events and remediation branches were created.

- Key assumptions were documented, with likelihoods assigned in percentages.

- Initial results were presented to a panel of peers, risks and assumptions validated and aligned upon or changed as required.

- Simulations were re-ran and final results were assessed to select base case strategy, with any opportunity cases and those options to be discarded.

A comprehensive risk profile of each well abandonment methodology was provided

- Cumulative probability percentage (i.e. X% of outcomes will achieve X days or better).

- The time difference between P5 (favourable) and P95 (unfavourable) outcomes.

- The larger the spread, the higher the risk and exposure to well conditions and/or heavy remediation operations.

- The smaller the spread, the more repeatable and robust the option is.

- A dramatic increase in time taken across a small incremental change in P outcomes. Reflective of contingency operations and requirement for remediation

- The point at which the distribution starts to tail.

- A grouping of probability outcomes that may be narrow or wide.

- A distinct peak within a probability band.

- The number of bands present within the density function.

Try free? Please contact our sales team here.